1018 cold drawn steel bar is composed of low-carbon steel and is widely used due to its versatility and formability. It can be used in many different applications, particularly those that do not require the strength of high-carbon steels. 1018 cold drawn steel bar has superior welding characteristics as well and is best suited for cold bending and forming applications. Additionally, it possesses increased strength if 1018 hot rolled steel bar does not achieve the desired mechanical properties.

Requirement Specifications we can meet:

- A108

- A193B7

- A193B7/A434BC

- A320L7/A193B7

- A434BD/A722MOD

- A449

- A722MOD

- F1554GR105/A193B7

- A36

- A572GR60

- A615GR75

- F1554GR36

- F1554GR55

- A576

- A354BC

- A354BD

Shapes & Sizes Available

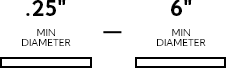

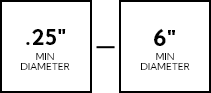

Square

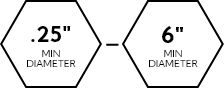

Hex

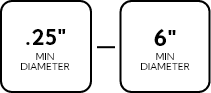

Round Corner Square

Flats