What Is Quenching & Tempering?

Quenching and tempering are two commonly used heat treatment processes that are done to raise the hardness and toughness of steel. Two steps are needed because while quenching increases hardness, it results in a very brittle material. Tempering lowers the hardness a little and puts some ductility back into the metal without taking it all the way back to its original condition.

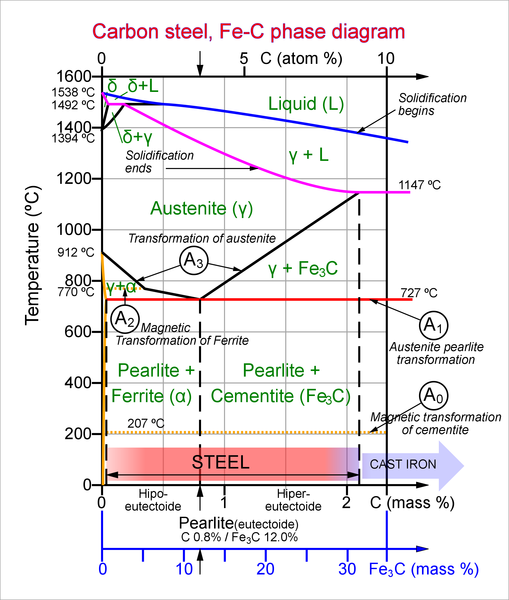

During these processes, crystals of iron and carbon form a variety of structures (called “phases”) that determine the strength, hardness, and ductility of the steel.

The Step-by-Step Process

1. Austenitizing Cycle

The first step is to heat the steel and allow it to soak at a temperature above the eutectic transition temperature. This temperature, slightly below the melting point, is the temperature at which carbon atoms can diffuse through the iron. This lets the iron change from a body-centered cubic (BCC) ferritic crystal structure to face-centered-cubic (FCC) austenite.

The temperature at which steel transforms to austenite is related to its carbon content, but at its lowest, when the carbon content is around 0.8%, is 1,333 degrees Fahrenheit (723 degrees Celsius). Time above the transition temperature is important because it allows the carbon to diffuse and forms more austenite.

2. Quenching

Before we explain quenching, it’s important to understand that if steel is removed from the furnace and allowed to cool in air, the austenite crystals will either transform back to ferrite or take on a pearlite structure, depending on carbon content. Pearlite is made up of layers of ferrite and cementite. Cementite has a complex crystal structure that raises hardness and strength, whereas ferrite is soft and ductile. Higher carbon content promotes pearlite formation.

Quenching is an accelerated cooling process that replaces this transition with a change from austenite to martensite. The process involves rapidly lowering the hot steel into water or oil. Water cools the steel faster, but for high carbon and alloy steels, this can cause cracking, which is why oil is used instead.

Martensite has a distorted BCC structure that results from carbon atoms not having time to diffuse through the crystal structure. This creates dislocations in the crystal lattice and puts a lot of stress into the steel.

3. Tempering

After quenching, steel is extremely hard but very brittle. As most applications for steel need a mix of hardness and toughness, this brittleness must be reduced, and this is done by tempering.

Tempering involves heating the steel again, but to a lower temperature than that used for hardening and quenching, holding it at that temperature for a period, and then letting it cool. Careful selection of temperatures and times will achieve the combination of hardness, strength, and ductility desired.

Low temperature tempering lets carbon diffuse through the martensite and relives stresses associated with the dislocations in the crystal lattice. This lowers hardness a little while increasing ductility.

Tempering at a higher temperature promotes the formation of cementite and increases toughness. As the temperature is increased, this lower hardness-higher toughness trend continues.

Which Materials Can Undergo This Process?

The quenching and tempering process is applied exclusively to ferrous alloys, as it relies on the changes in crystal structure caused by carbon diffusing through iron. (Many nonferrous alloys can undergo precipitation hardening, which produces similar results.)

The carbon content of steel is the main factor in determining temperatures, times, and levels of hardness and toughness achieved by quenching and tempering. For low- and medium-carbon steels, quenching and tempering significantly improves both hardness and strength. As the proportion of carbon rises, the resulting heat-treated steel tends to be more brittle but more wear-resistant.

For alloy steels, the presence of elements like manganese, chromium, nickel, and molybdenum enhances the benefits of quenching and tempering.

Benefits of Quenched & Tempered Steel Bar

Quenching and tempering steel bar changes the grain structure to make it harder and stronger while reducing brittleness and preserving ductility. These enhancements make it easier to form into the shapes needed in the end product without cracking. In some circumstances, it can also permit the use of low- or medium-carbon steel rather than more expensive alloy steel.

Another important benefit of quenching and tempering steel bar is to create a more consistent and uniform structure throughout its length and across its section. Combined with the reduction in internal stress, this results in more predictable secondary processing with less waste.

- Increased strength

- Increased toughness

- Less distortion

- More predictable physical properties

Learn More Today

King Steel Corporation is an industry-leading provider of steel bar, wire rod, and wire products. We also provide extensive processing capabilities, including quenching and tempering. You can visit our website to learn more about our specific capabilities, or visit our blog for more informational resources.