Properties

9260 steel is a high-silicon spring alloy known for its excellent flexibility and resilience. These characteristics make this grade ideal for high-stress applications like the heavy-duty springs commonly found in automotive and railway suspensions. Its high silicon content not only enhances the steel’s strength and hardness but also improves its shock resistance and fatigue life.

| Chemical Properties | |

|---|---|

| Carbon | 0.56 – 0.64 |

| Manganese | 0.75 – 1.00 |

| Silicon | 1.80 – 2.20 |

| Phosporus | 0.035 (max) |

| Sulfur | 0.04 (max) |

| Chromium | 0.60 – 0.90 |

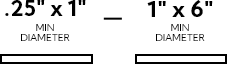

Shapes & Sizes Available

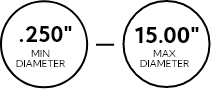

- Rounds

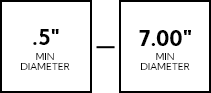

- Square

- Round Corner Square

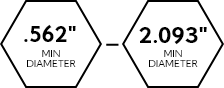

- Hex

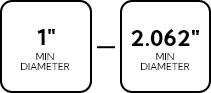

- Flats

Requirement Specifications we can meet:

- ASTM A108

- ASTM A576