303 stainless steel is commonly used because of its good machinability and corrosion resistance. King Steel is capable of supplying 303 stainless steel in bar, wire, or wire rod. Please inquire for special shapes.

Composition

303 is a non-magnetic, austenitic grade of stainless that can’t be hardened through heat treatment. Like all grades of stainless, 303 gets its properties primarily from the large chromium and nickel additions to the iron. The sulfur content, though small, has an appreciable effect on properties.

In detail, the composition of 303 stainless steel is:

- Chromium: 17-19

- Nickel: 8-10

- Manganese: 2.0 (max)

- Silicon: 1.0 (max)

- Phosphorous: 0.2 (max)

- Sulfur: 0.15 (min)

- Carbon: 0.15 (max)

Benefits

The inclusion of sulfur in 303 gives it better machinability than other stainless steel grades. This is why it’s sometimes referred to as a “free machining” grade.

As a stainless steel grade, it also has natural corrosion resistance, although it is lower than other grades, such as 304.

Additionally, 303 stainless steel is tough and has good ductility. Yield strength is 30,000 PSI (207 MPa) minimum, and minimum tensile strength is 75,000 PSI (517 MPa).

Common Uses

303 stainless steel bars are ideal for parts that need significant turning, milling, and drilling. Its free-cutting nature minimizes tool wear, and high metal removal rates are achievable. It should not be used where exposure to chlorine is likely, such as on boats and marine oil exploration equipment.

Ideal applications for 303 include:

- Shafts for Machinery & Rotating Equipment

- Screws, Studs, & Bolts

- Dowel Pins

- Hinges

- Gears

- Linkages

- Electrical Switchgear

- Aircraft Fittings

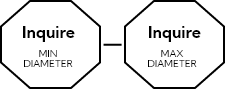

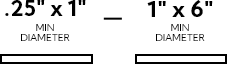

Shapes & Sizes Available

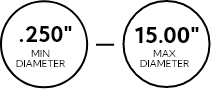

- Rounds

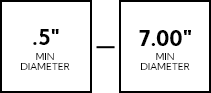

- Square

- Round Corner Square

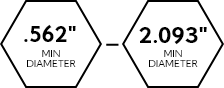

- Hex

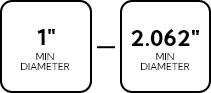

- Octagon

- Flats

- Round Edge Overall Flats

- Round Edge Overall Flats