Properties

200 series stainless steel is a cost-effective alternative to the 300 series. It’s an austenitic steel composed primarily of chromium and manganese, which gives it good corrosion resistance and high formability for mild environment applications. 200 stainless steel, in bar form, is used mainly for automotive structural components, manufacturing equipment, and architectural frameworks.

Please note that chemical properties listed below will vary based on the specific grade chosen within the 200 series.

| Chemical Properties | |

|---|---|

| Chromium | 16 – 18 |

| Manganese | 5.5 – 7.5 |

| Nickel | 1.5 – 5.5 |

| Nitrogen | 0.25 |

| Carbon | 0.15 (max) |

| Silicon | 1 (max) |

| Phosphorus | 0.060 (max) |

| Sulfur | 0.030 (max) |

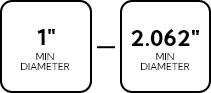

Shapes & Sizes Available

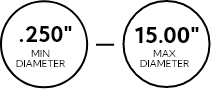

- Rounds

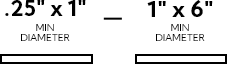

- Flats

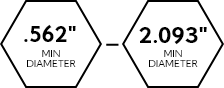

- Hex

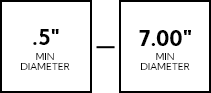

- Square

- Round Corner Square