Properties

For applications that require a larger spectrum of strength, 1045 hot rolled steel bar is a great fit. It is formed using a medium-carbon steel and can be induction hardened for applications with higher strength requirements. 1045 steel bar can be welded using a variety of methods and it has decent machinability, as well as moderate to high strength. This grade of steel bar is most often utilized in fasteners, crankshafts, couplings, axles and other forged parts.

Shapes & Sizes Available

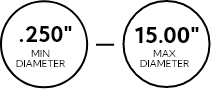

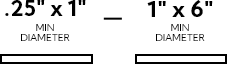

- Rounds

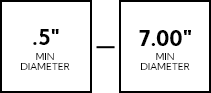

- Square

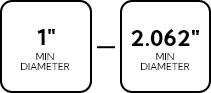

- Round Corner Square

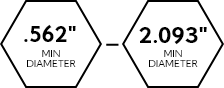

- Hex

- Flats

Requirement Specifications We Can Meet:

- ASTM A29

- ASTM A576

- JDM QL-2 certified